Frequently Asked Questions

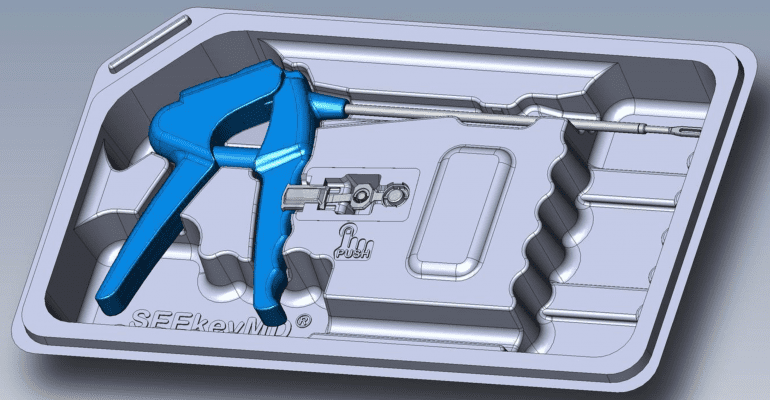

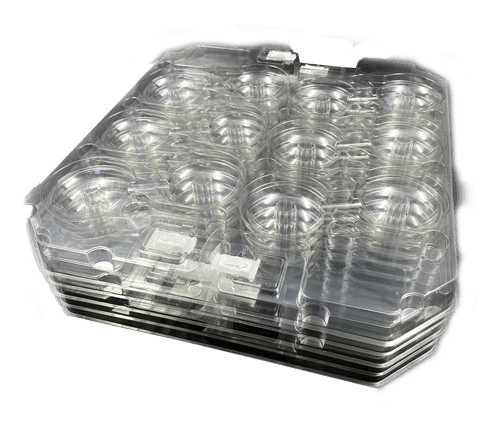

SEEkeyMD® is a miniature-sized injection molded retainer used to secure and release a device in a thermoformed tray.

It replaces special button-snaps and special one-way retainers. This paradigm shift provides an on-the-shelf system that expedites development speed, standardization, plastic reduction, gives product continuity assurance, and leverages volume to reduce cost.

Once upon a time…After many months of snap button revisions, a customer held a design review to accept or reject them. Some of the attendees said the snap security was too tight, while others thought it was too loose. The project lead declared, “We’re searching for Goldilocks!” and the meeting adjourned with no resolution. I knew there had to be a quantitative way to ensure the security and release of a device when using a tray.

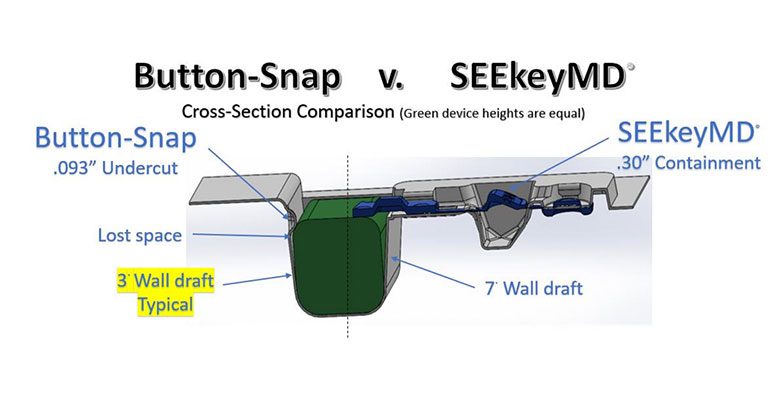

- Aluminum weld is weaker than the parent material, thus they should only be modified from a material safe condition.

- They are designed for only one material thickness.

- They’re time-consuming to modify.

- They’re the most critical geometry to the security of a device, yet they have the highest rate of tool wear.

- Many times they are measured with a subjective attribute test with both the test device and tool obtaining wear.

- They require a +/- .005” tolerance to work, yet most drawings have an +/- .020” tolerance on them.

- They require opposing counter forces, which cause a popping motion when opened, displacing the product.

- Despite an engineering preference for the push release feature, marketing is currently comfortable with “the way it has alway been done.” It loads and releases just like a snap-button.

- Perception – Most compare a snap-button area to the area of a SEEkeyMD®. The space used for a SEEkeyMINI™ is found when laying them on top of a current tray which has snap-buttons. In a nut shell… people want the same footprint as snap-button trays.

- The device capture area, speed-to-market, logistical and plastic reduction is superior to current methods.

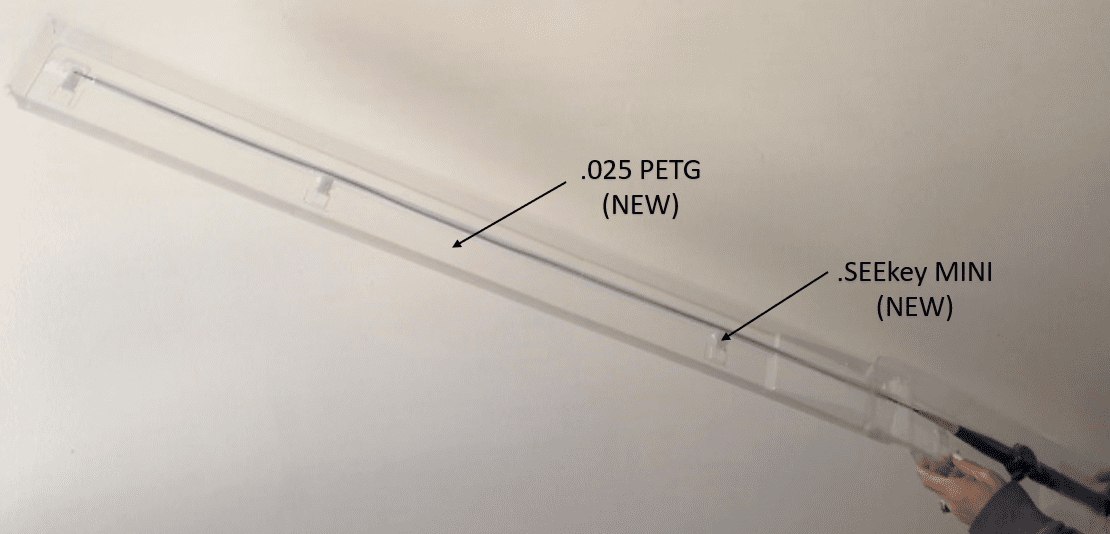

SEEkey™ provides a minimum of .005″ base tray gauge reduction. While this amount may seem insignificant, the sustainability impact is considerable. For example: The weight of a 6″ x 10″ x .040″ PETG part is 50 grams. The weight of a 6″ x 10″ x .035″ part is 44 grams. This means FIVE full-size SEEkeys need to be added to the 035″ part to equal the same size part in .040″. For this reason, SEEkeyMD® competes with integral button-snaps and will have a significant saving against a retainer.

Featured Articles

Videos

Understanding SEEkey®: (5-Minute Videos)

Qualified Base Tray Suppliers

Qualified rigid tray providers who have demonstrated a +/- .005” material side variation using the SEEkey™ system.

Qualified Plastic Sheet Suppliers

Resin Data

DOW™ HDPE DMDA-8920 HEALTH+™

Technical Highlights

Complies With:

Applications:

Features:

Compatable Sterilizations:

Documentation

Patents

Awards

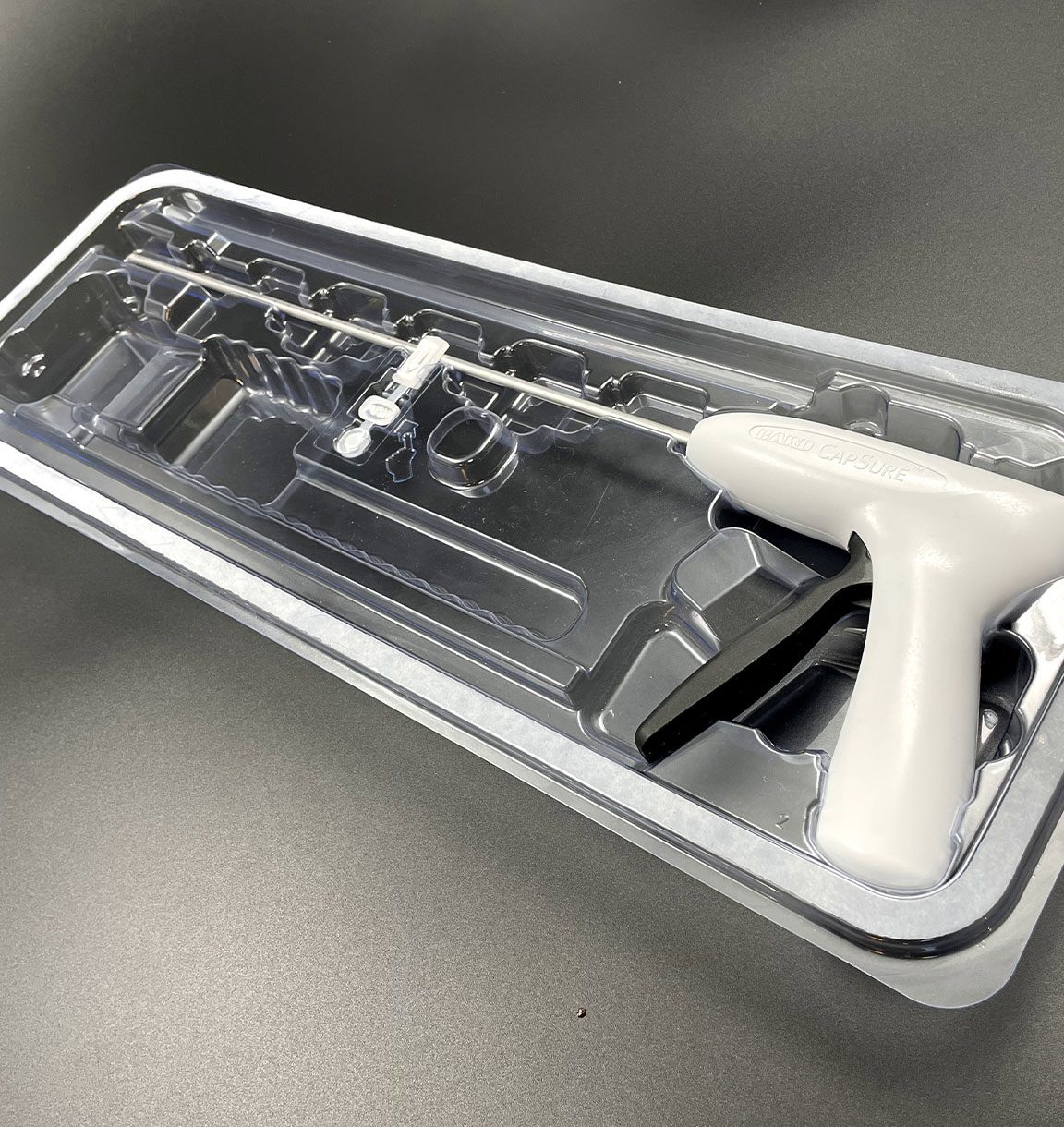

This packaging innovation provides a new method to obtain cost savings and device security, while improving the nurse experience. After attempting to reduce costs with three traditional packaging methods cost savings were finally achieved with a miniature injection molded retainer (SEEkeyMD®) that becomes integral to the rigid tray. The device security and single push device release is easily recognized, but what isn’t recognized is the 25% plastic reduction the SEEkeyMD® system allows for. This new approach provides vision to the device before opening, eliminates all packaging waste from the sterile field, and eliminates the sterile barrier integrity risks associated with the prior flexible pouch system. This new packaging provides: 35% overall cost savings, 75% assembly time savings, and a 24% hospital shelf-footprint savings.

The innovative Integer Rigid Handing Tray Optimization featuring SEEkey® system, conquers the popping/flying issues caused by traditional undercut snaps on their wire spool packaging. The thin 24-mil tray is manufactured by Merrill’s Packaging cuts plastic use by 44%, saving 24% in costs.

The tray’s versatility in locking and unlocking offers efficient product organization, while dual nested spacing levels reduce secondary packaging and improves sustainability. The continuous stack utilizes both sides of each tray to eliminates tray quantity while amplifying the strength to pass the rigorous testing requirements.

What Our Customers Have to Say

“[SEEkey™] allows the end user to remove the device freely and safely from the tray, as opposed to the ridge tray designs that have overly aggressive snaps for device security resulting in potential damaged products and frustration through the end user having to aggressively pull, twist, bend, shake, and even pry the device from its package. Therefore, it is my opinion that this new design increases efficiency and the end user satisfaction while minimizing the sterile field waste.”

Charles Kanazeh – Associate Director, Labeling & Packaging Engineering – BD Interventional – Surgery

“You don’t see something this revolutionary in the (plastic) film area. The cost-saving potential and the design aspect – it is really impressive. I mean, it’s just something really different. This is something that you could talk about that’s totally above and beyond what the other companies have. It’s great, great design.”

Steven Bakus – Senior Packaging Engineer, BD Surgery Packaging Engineering

“The product security that the SEEkey offers is second to none. It cuts down on development time substantially – I’m talking 50% or greater. And then the environmental benefits are unmatched. The reduction in plastics is just outstanding, and as we continue to move toward sustainable solutions, I think SEEforming could play a major role.”

David DiVaccaro – DiVaccaro Consulting Group, LLC

“SEEkey™ is the first real design innovation in our business. I’ve been in this industry for almost 28 years now. This is the first real pure design innovation allowing us to offer you know real sustainable solutions which allow for savings in plastic and improved packaging functionality. It is quite helpful from a pricing and usability standpoint.”

Lee Krueger – Account Executive, Merrill’s Packaging